Speed Kompost

M/s Kan Biosys Private Limited, Punjab, Haryana

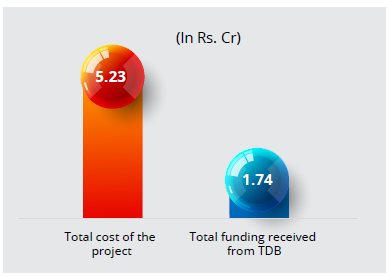

Technology Development Board (TDB) entered into an agreement on 27th March 2018 with M/s Kan Biosys Pvt. Ltd., Pune for Project on “Development and commercialization of straw utilization technology: In-situ Accelerated and Sustainable Rice Straw Decomposition (ASRSD). They received a loan assistance of Rs. 1.74 crore against the total project cost of Rs. 5.23 crore.

About the Technology

Kan Biosys has developed a novel aerobic process for in situ incorporation of rice stubble using Speed Kompost. In-situ Accelerated and Sustainable Rice Straw Decomposition (ASRSD), which was new not only to the firm and market but also new for the world. One of the major benefits of this technology (ASRSD) is that the microbial cultures are directly added to the soil where they aid in cellulose, starch and silica conversion. This technology involves minimal use of machinery and water. This is an economically viable option to farmers for management of rice straw and at the same time maintaining soil health for higher yield and pollution abatement measures. The technology is India’s solution to rampant stubble burning. Reports of 3 years trials confirm the beneficial effects of ASRSD on soil properties and more than 20 percent increase in yield of wheat which is cultivated after rice straw utilization by ASRSD.

Commercialisation of the Product

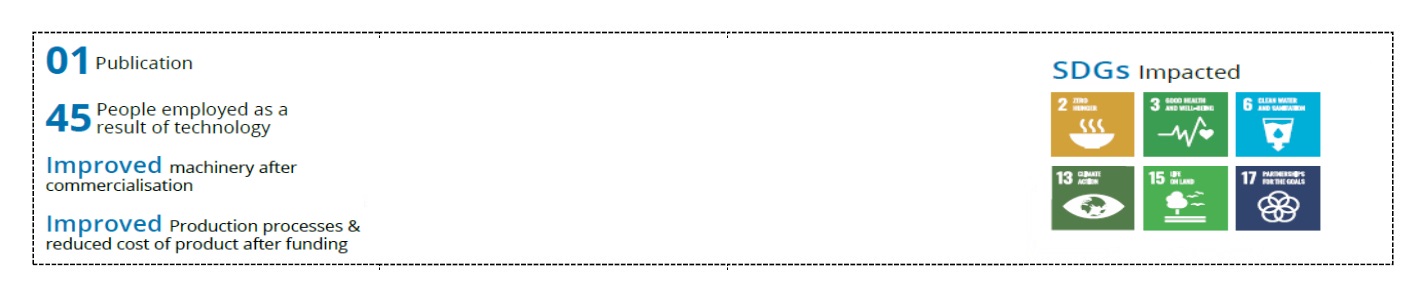

The project trials were undertaken in Punjab & Haryana. It was developed using in-house technology. A total of 31,975 units were sold in the year of commercialization itself. Total revenue of Rs. 1.35 crore has been created from the commercialization year and the subsequent year. The company has 16 state of the art microbial products developed using in-house technology. All products are marketed in India and exported to over 5 countries routinely. Field trials were initiated at Punjab Agricultural University and Haryana Agricultural University to scientifically evaluate the impact of technology for straw utilization. Speed Kompost TM Quality control laboratory was upgraded to ensure product quality as per FCO norms. The equipment procured were Kel Plus, Fume Hood, accessories for AAS, etc. The Speed Kom post TM production capacity was upgraded to 1000 tonnes/annum. The equipment procured were fermenter, water storage tanks, mixers, conveyer belt, compressors, rotary shakers, etc. Marketing strategies used for successful implementation of ASRSD included farmer and dealer meetings, radio jingles, hoardings, television/newspaper/magazine advertisements, press conferences at Delhi and Ludhiana, participation in Krishi mela at Punjab Agriculture University (PAU), and participation in TDB exhibition. Around 120 tons of the product has been sold on over 30,000 acres of rice fields since 2018 leading to 3000 plus satisfied rice farmers.

Impact of funding

| In-situ Accelerated and Sustainable Rice Straw Decomposition (ASRSD) is sold not only in India but also in other countries including North America. |